Take advantage of the world’s most diverse machining process with Lufkin Rubber & Gasket. Our waterjet fabrication capabilities will give you access to custom parts cut from virtually any material on Earth. No matter the material or shape, your part will be produced with a clean edge & impeccable accuracy. We’re your premier waterjet cutting service and our waterjet cutting machine is here to cut your parts! Contact us today for the best service in waterjet cutting!

Why waterjet?

Our waterjet cutting services offers customers access to parts cut from virtually any material, with impeccable accuracy, total repeatability, and easy revision. Our Omax waterjet can cut thru metals, plastics, rubber, urethane, wood, stone, compressed gasket sheet, and much more. What can we cut for you?

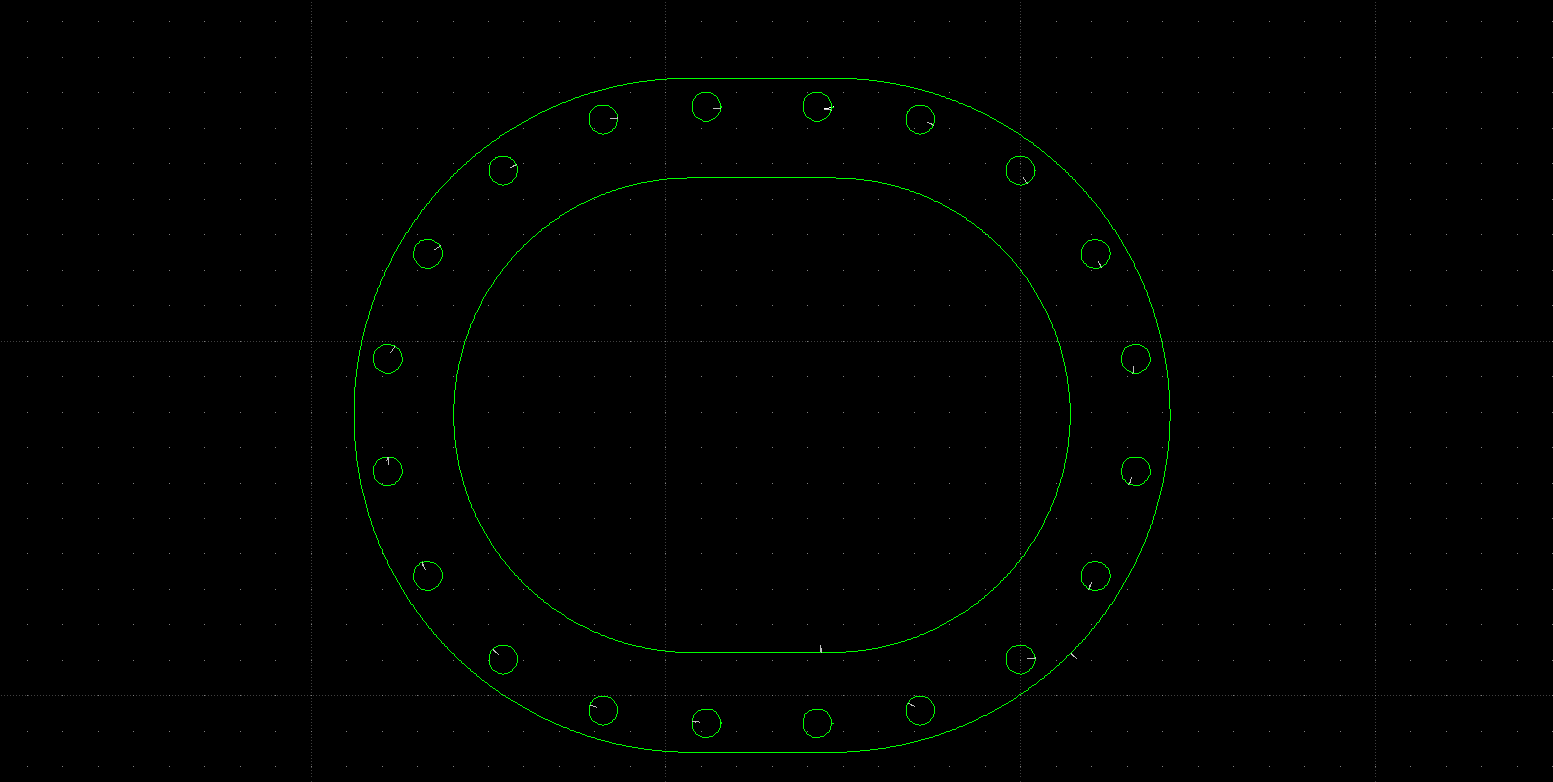

Custom Gaskets

Waterjet cutting is the perfect tool for custom gaskets! Order custom prototypes or large production runs without paying premiums!

Thick Materials

Harness the power of water to cut up to 6” thick materials -even hardened metals!

Metal Parts

All known metals can be waterjet cut. Stainless, aluminum, copper, brass, titanium, you name it! We can cut metal with the utmost precision.

Plastic Parts

Order custom plastic parts from Lufkin Rubber & Gasket! Waterjet cutting is a great tool for cutting any kind of industrial plastic!

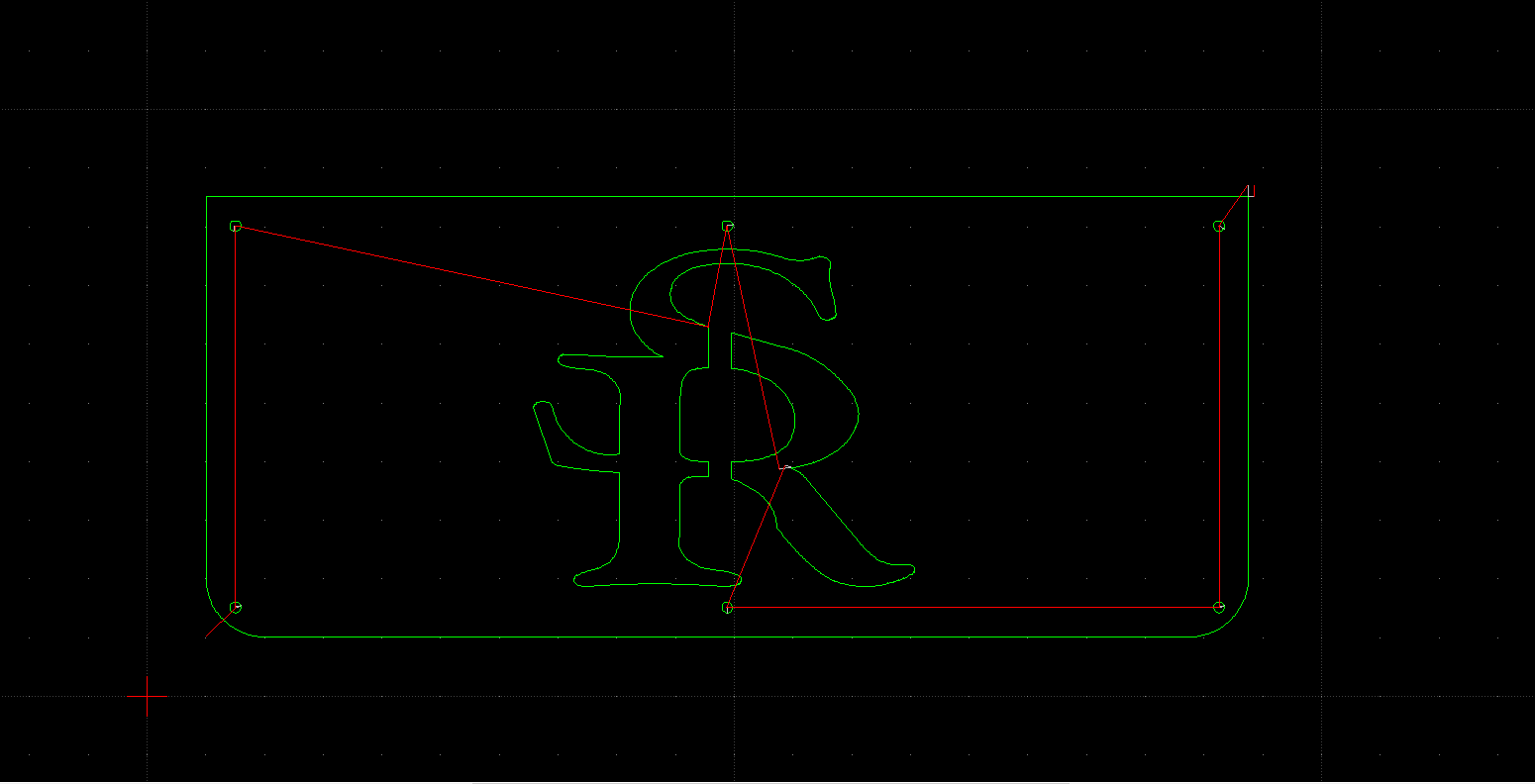

Decorative

Waterjets are great for decorative and ornamental applications like floor & gate emblems, jewelry, signage, and much more!

CAD Design

Lufkin Rubber can design your parts from scratch, import your CAD files, or program from existing samples.

Waterjet Gallery

Waterjet cutting advantages

Abrasive waterjets can cut virtually any material, including glass and reflective materials, and a wide range of material thicknesses. Some OMAX customers report cutting material up to 18 inches thick.

Abrasive waterjet machining is a cold cutting process and creates no heat-affected zones (HAZ), therefore it doesn't change the material properties or leave heat-hardened edges.

Set-up for cutting jobs on abrasive waterjets is quick and easy.

Multiples of the same part can be cut at one time from different types of material simply by stacking the various sheets of material on the waterjet.

No harmful vapors are emitted with abrasive waterjet cutting.

A waterjet's cutting tool never gets dull.